We provide a full range of EDM manufacturing processes that are particularly useful for creating complex shapes and working with hard metals that are difficult to machine with traditional methods.

EDM is a crucial manufacturing process, especially for high-precision applications and complex geometries. With unique advantages such as being able to cut through hard metals like tool steel, tungsten, and titanium with high precision, even when traditional machining methods would struggle. Our investment in our EDM machines means that we can offer faster cutting speeds and better surface finishes. Due to its precision and ability to work with hard metals, it is ideal for certain industries, such as aerospace, defence, and telecommunications which require intricate parts that can withstand extreme conditions. The EDM process is also ideal for the medical industry to create components such as implants and surgical instruments.

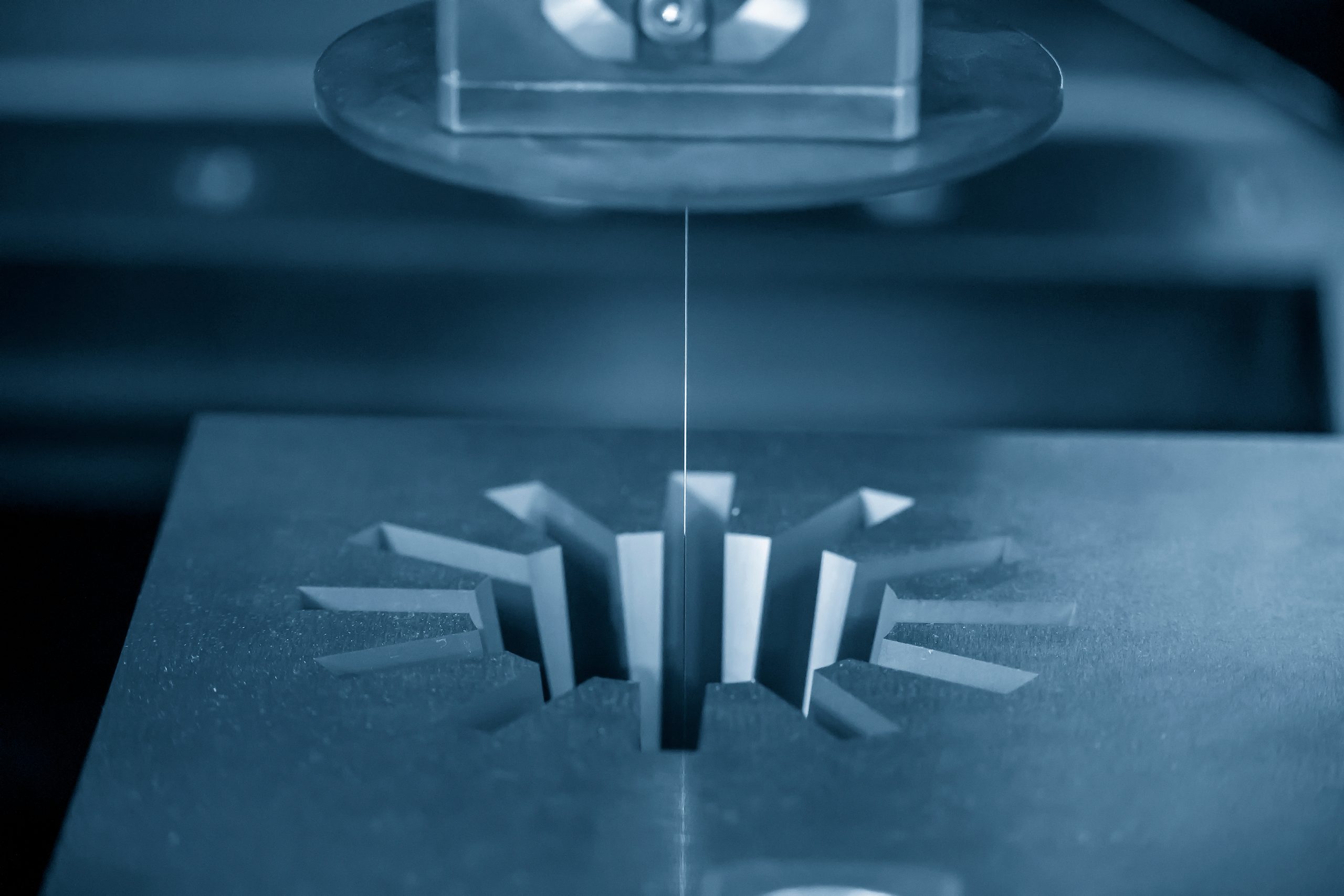

Our wire EDM process is typically used for intricate cuts and tight tolerances, making it ideal for producing components with complex geometries, such as those found in aerospace, automotive, and medical applications.

We commonly use this manufacturing process for mold and die manufacturing, also allowing for the creation of complex shapes and undercuts that would be difficult with conventional machining.

We can use this process for making starter holes for wire EDM or for drilling holes in difficult-to-machine materials. We can also use hole drilling to create holes with high precision.

RST Engineering Limited

Unit 1 Youngs Industrial Estate

Stanbridge Road

Leighton Buzzard

Bedfordshire

LU7 4QB

COPYRIGHT © RST Engineering Ltd. 2024 ALL RIGHTS RESERVED.

Privacy Policy | Terms & Conditions | Sitemap

Site designed & built by CO-LAB